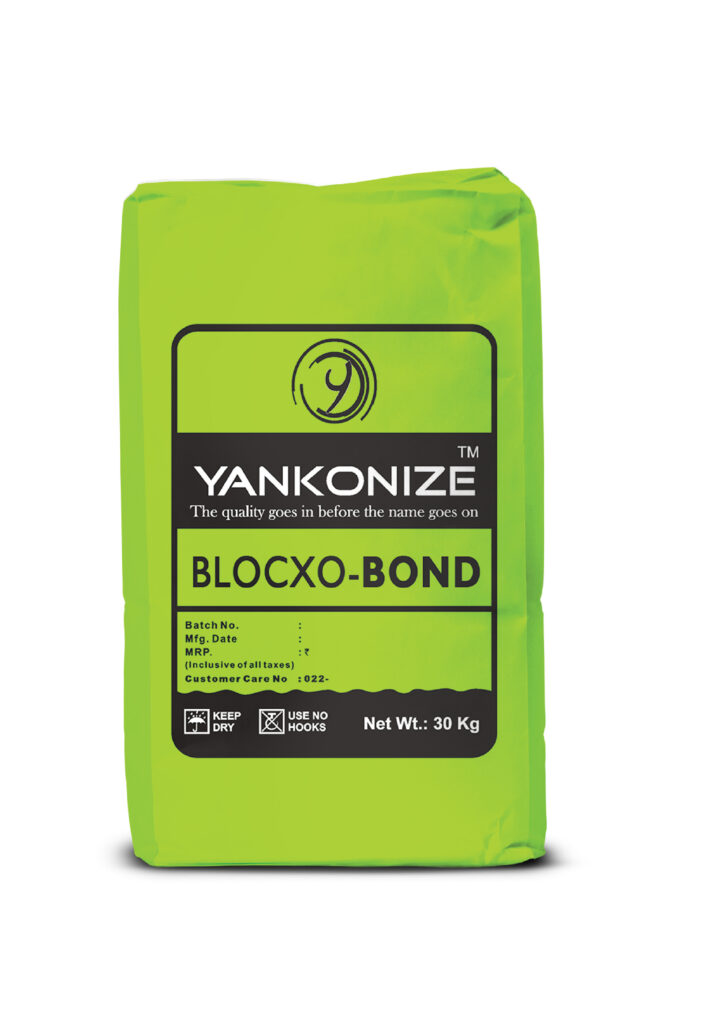

BLOCXO- BOND

Thin jointing material for laying AAC blocks, fly ash bricks, concrete blocks etc

YANKONIZE BLOCXO-BOND is a versatile thin jointing material for laying AAC blocks, fly ash bricks, concrete blocks etc. YANKONIZE BLOCXO-BOND is specially designed to provide stronger, much more durable bonding between the blocks and superior adhesive strength. It replaces conventional cement and sand mix mortar.

YANKONIZE BLOCXO-BOND is made from cement, graded sand and selective additives. The unique chemical combination enables (BLOCXO-BOND) to more compact, thinner and more versatile. At only 3mm thick it is thinner than the conventional mortar which is between 12-18mm. it is Ready to use so it is easy to use and also ensures the compaction of interlocking bricks making the bonds tougher and more durable.

FEATURES & BENEFITS

- Pre-mixed and ready to use. Just add water at site.

- No water curing is required after application.

- Easy to mix. Much faster to apply due to its superior flow-ability and water retention properties.

- Thinner jointing material with very high adhesive strength improves overall masonry strength and bearing capacity.

- Thinner layer of application for lesser shrinkage and seamless structure.

- (BLOCXO BOND)-Quantity of Binder is far less than conventional mortar.

- Raking of joints is not required before plastering.

- Ready for plastering just after 24 hours.

- Negligible Seepage/water percolation through joints because to integrity of mortar joints with masonry units.

- Eliminates lengthy process of site mixing, transport and storage of all individual materials.

- Raw materials are processed, reducing the chances of efflorescence.

- (BLOCXO-BOND) jointing Agent is made from Eco- friendly materials.

INSTRUCTIONS: PRECAUTION / STORAGE

PRECAUTIONS :

- Though (BLOCXO-BOND) contains no toxic materials, still care should be taken to avoid dust inhalation while mixing and handling in case of contact with eyes or face, wash with plenty of clean water.

- Keep it in a dry place and out of reach of children.

- Persons who are allergic to cement should take proper precautions before use.

STORAGE: - (BLOCXO-BOND) should be stored in a dry place for better results.

- (BLOCXO-BOND) should be used within 6 month of its production.

TECHNICAL INFORMATION

- COLOUR: GRAY

- APPEARANCE: FREE FLOWING POWDER

- WORKABILITY: VERY GOOD

- WATER DEMAND #: 25 - 30 %

- TENSILE ADHESION STRENGTH @ 28 DAYS: 0.8N/Sq.mm

- HARD DRY #: 24 hrs

- POT LIFE: 1 - 2 Hrs

- SELF CURING #: YES ( NO ADDTITIONAL WATER CURING IS REQUIRED)

AREA OF APPLICATION

WHERE TO USE:

Laying and jointing of masonry units like fly ash bricks, concrete blocks, hollow blocks, AAC blocks etc.

Jointing of pre-stressed concrete slabs, panels.

Jointing of cement-concrete floor tiles.

HOW TO USE

- A) SURFACE PREPARATION:

The masonry units should be clean, with no loose particles or dust for better bonding.

The surface must be structurally sound. Efflorescence & any other contaminant which could impair the natural bond should be removed.

Surface defects such as cracks, holes or voids should be repaired prior to application.

The surface of masonry units should be slightly wet prior to application of jointing Mortar.

- B) MIXING:

BLOCXO- BOND jointing Mortar must mix with water thoroughly before use. It is advisable to use a mechanical stirrer for uniform mixing to save time, labour and for maximum workability effectiveness.

Ensure that no powder is left unmixed at the bottom of the vessel.

Use a clean vessel/bucket which does not have any hole or cut and add some water in the powder

- C) METHOD OF APPLICATION:

Layout the wall where jointing Mortar is to be used and mark openings like door, windows or any architectural appurtenances.

Apply a thin uniform layer of jointing Mortar 3 to 4 mm thick on the clean & leveled surface of masonry units using proper trowel.

Place the next course of masonry units on the evenly laid jointing mortar bed in proper line & level. Each masonry unit shall be properly bedded and set in position by gently pressing with the handle of a trowel.

After placing the first unit, apply the jointing mortar of same thickness on both the sides of the unit, keeping continuous check for the line & level.

Inside face of the masonry unit shall be buttered with mortar before the next unit is

laid and pressed against it especially in case of bricks.

Clean the excess material, if any immediately. Continue the procedure for the entire masonry work.